Dave McD's

PBF (Pizza Box

Flyer)

Original design inspired from an idea

Original design inspired from an idea

by my buddy John Petersen (Foamguy),

and developed with input from a thread on

RC Universe.Com

Type: Indestructible Flying Wing.

Materials: 4mm Coroplast, pine/oak, alumimun.

Wingspan: 24"

Wing length: 24". (4" are moveable elevons.)

Wing area: 576 square inches.

Airfoil: Symmetrical (Hey, it's flat!)

Vertical tail: 6"x6", (3" is moveable rudder.)

Fuselage: 3/8" x 3/4" x20" pine,

Motor mount: Hardwood (pine or oak)

Landing gear: None.

CG: 5.5" to 6.0" back (23%-25%)

Channels: 4. (elevons, throttle, rudder.)

Engine: OS 40FP with Grish 10x4 prop.

Fuel tank: 4 ounce.

Radio: Futaba S-148 servo (x4), R-127DF Rx,

4.8 volt 270 mah battery.

Weight: 2 pound, 8 ounces.

What is a PBF?

A PBF is a nearly indestructible square and flat flying wing that easily

performs extremely tight and quick aerobatic maneuvers at super slow flying

speeds.......and it only costs about $5 of parts and a few hours of labor to build.

Flying a PBF feels like flying an extremely maneuverable overpowered feather.

I've had more fun with this simple little plane than any other RC plane I've ever owned or

flown! And after flying RC planes since 1969, that's a LOT of planes!

The PBF Story

The idea of a square flying wing started out as brainstorm by my internet buddy, John

"Foamguy" Petersen. John built an experimental OS .40LA powered

"Squareplane" with an airfoiled coroplast wing and posted a picture of it in

flight on RC Universe.Com under a

thread called the "Flying Pizza Box". If you browse through my RC Air Force,

you'll no doubt notice that I love flying wings. The idea of a square flying wing sounded

like fun, so I put everything else on hold and started workng on my own version of John's

Flying Pizza Box. It ended up flying so much better than expected that I posted

detailed photos of it on RC

Universe.Com so others could build one too. Shortly thereafter, the Flying Pizza

Box thread caught fire, soon followed by the Pizza Box Flying thread, and then the Build

Your Own PBF thread.

Reading through these old threads will explain a lot about the history of how John's

original Flying Pizza Box evolved into what has become known on RC Universe.Com as the PBF. And

if you're seriously considering building a PBF of your own, take the time to read through

these old threads because they contain a wealth of information that isn't included on this

web site, especially the first one.

"Build

Your Own PBF" RCU thread

"Flying Pizza Box" RCU thread

"Pizza Box Flying" RCU thread

"Dave McDonald the Father of Pizza Box Fliers?" RCU thread

Those threads also proved that John and I aren't the only "weird guys who like cool

stuff"......errrrr...... I mean "cool guys who like weird stuff".

Thank you John "Foamguy" Petersen for getting me started on this PBF project!

I love this plane!!!

NEWSFLASH!!!

10/07/02

After some arm twisting by Dean "Tattoo" Tuinstra of S.P.A.D. fame,

the PBF now has it's own forum topic on SPAD

World.Net,

the official discussion forum of the S.P.A.D. (Simple Plastic Airplane Designs) web site.

If you're looking for the latest information about the PBF and other similar

planes,

be sure to check out the PBF

forum on SPAD World.Net.

UDDATE 4/4/03:

The PBF seems to have sparked an interest in developing other SPAD 3D and Fun Fly designs,

such as the QHOR by Dean "Tattoo" Tuinstra. As a result, the old PBF forum on SPAD World.Net has been renamed to SPAD X-Treme....3D and Fun

Fly in order to include other highly maneuverable SPAD fun fly designs, such as the

QHOR.

Flexible Flat Flying Wing = Fun Flyer's

Fantasy

OK, it's just a single flat piece of 4mm (3/16") coroplast that I mail ordered from Harbor Sales. But the PBF is

an absolutely amazing airplane! The PBF will do tight inside/outside loops,

extremely tight turns, quick rolls, upright/inverted spins, flat spins, hovers, torque

rolls, and it slow-flys better than any other plane I've ever flown. For on the deck

3D flying, or hovering around at ridiculously slow speeds, the PBF is the best I've seen

yet. In fact, the PBF has proven to be one of the most enjoyable RC planes I've ever

flown in my 33 years of RC airplanes.

PBF + Indestructible = Fearless

Flying

The PBF has also proven to be nearly indestructible. In fact, the more I fly it, the

more the PBF reminds me of a Realflight plane instead of a real plane. Unlike any of my

other RC planes, I've pretty much lost my fear of damaging the PBF in a crash......which

is one of the things that makes it so much fun to fly! If you dork the PBF, you

usually just restart the engine and go flying again....sort of like the spacebar on

Realflight.

The PBF has also proven to be nearly indestructible. In fact, the more I fly it, the

more the PBF reminds me of a Realflight plane instead of a real plane. Unlike any of my

other RC planes, I've pretty much lost my fear of damaging the PBF in a crash......which

is one of the things that makes it so much fun to fly! If you dork the PBF, you

usually just restart the engine and go flying again....sort of like the spacebar on

Realflight.

The PBF has proven to be so rugged and capable of flying so slow that we've been using

them for full contact combat. Here's my PBF #1 bumping Tim's PBF from below.

Unfortunately, when my PBF bumped Tim's PBF, it killed my engine and PBF #1 fell to the

ground......undamaged of course. But the most fun we've had with PBF Combat has been

"Prop Blast Fighting", where you try to position your PBF so the prop blast

knocks the enemy PBF to the ground. (Video link to "Prop Blast Fighting"

Combat is at bottom of this page.)

If you love to fly 3D with the profile or competition fun fly type planes, then you will

love flying a PBF! I love to horse around with my Stickit IV at

extremely low altitudes, but the fear of crashing it still prevents me from trying certain

maneuvers at ground level. The OS 40FP powered PBF will do most all of these same

close in maneuvers and more, but without the fear of damaging it in a crash. In

fact, I've completely lost my fear of the PBF hitting the ground if I screw up a

maneuver. This has given me the confidence to attempt some maneuvers with the PBF

that I still only dream about doing with my Stickit.

Like the Stickit

type planes, the PBF isn't meant to be flown fast, and would probably become

uncontrollable at flat out speeds, especially if using a .40 size engine. Instead

the PBF flys best with the nose of the plane pointing up anywhere from a 30 to 75 degree

angle, which is usually referred to as High Alpha Flight. In high alpha flight, the

PBF depends heavily on the prop blast to stay airborne. And at these super slow

speeds, the prop blast over the elevons is also needed to maintain pitch and roll control

in very nose high flight.

PBF + 3D = Fearless 3D

Lately I've been having a ball doing "Catch and Goes" with my PBF. As the

PBF slowly passes beside me, I reach out and grab the wingtip. Then relaunch it

with a sidearm toss. In fact, by truly hand launching the PBF like a Frisbee,

complete with the wrist-flick, the PBF can be directly hand launched into a single barrel

roll. It looks like a really bad hand launch, but the PBF completes the full barrel

roll without even touching the sticks. It looks scary, but it's not, which makes it

even more fun! (Video links to PBF "Catch and Goes" and the "Barrel

Roll Launch" are at bottom of this page.)

The PBF will easily roll with full aileron deflection while hanging on the prop. In

fact, the PBF will even do a true torque roll without cheating with the ailerons, but I'm

not good enough yet to hold it there for more than 2 or 3 turns. And since the PBF

is almost indestructible, you can afford to do these hanging rolls less than a foot off

the ground if you feel like it. It almost makes you feel like Quique

Somonzini.........well.....maybe for a few nanoseconds at least. (Video link to PBF

Torque Rolls at bottom of this page.)

PBF + Fearless =

Overconfidence

Since I no longer have any fear of damaging the PBF in a crash, I've also been

experimenting with loops, super tight turns, hovering, and maneuvering the PBF in low

level inverted flight just to see what it's capable of doing.......and to find out what

I'm capable of doing. Needless to say, I've dumped the PBF into the ground many

times attempting this kind of risky flying, but at the most the damage has been a broken

prop, and an occasional cracked motor mount beam. But usually there is no damage at

all.....especially when using the flexible nylon props such as the Grish. My Stickit would have

been reduced to splinters by now if I would have treated it like this.....which is exactly

why I haven't attempted this stuff with my Stickit. (Video

link to stupid PBF stunts at bottom of this page.)

PBF Spins and Spin Recovery

Spins and flat spins with the PBF are a whole new world of fun, but the spin recovery

technique on a PBF is exactly backwards from the technique on a "normal"

plane. At first, my PBF would sometimes enter an unintentional spin. It

finally dawned on me that the usual cause of these unintentional spins was making large

rudder inputs at very slow speeds while the elevator was nearly at neutral. This

sometimes causes the PBF to enter a violent and tight spin....sometimes upright.....and

sometimes inverted. To recover, the first thing you have to determine is whether

it's an upright spin, or an inverted spin.

To get out of an Upright spin, apply full UP (yes, UP) elevator control, and add power. If

it still won't come out, leave the full UP elevator in there and try adding rudder in the

SAME direction as the spin until the PBF transitions from an out-of-control spin into a

tight spiraling turn. Once it begins spiralling instead of spinning, you can easily

resume flying from there. But if you give it full down elevator in an upright spin,

it will continue to spin all the way to the ground.

To get out of an Inverted spin, apply full DOWN (yes, DOWN) elevator control, and add

power. If it still won't come out, leave the full DOWN elevator in there and try adding

rudder in the SAME direction as the spin until the Pizza plane transitions from an

out-of-control spin into a tight spiraling turn. And again, once it begins spiralling

instead of spinning, you can easily resume flying from there. But if you give it full up

elevator in an inverted spin, it will continue to spin all the way to the ground.

Want to see the PBF do an inverted flat spin? With the PBF nearly vertical and

hanging on the prop, apply full right aileron control and a just a little bit of up

elevator. This will often cause the PBF to enter and maintain a very flat inverted

spin if you keep the stick at full right aileron with just a touch of up elevator.

Sometimes adding full right rudder helps to enter the Inverted Flat Spin.

To get out of an Inverted Flat Spin, neutralize the rudder and aileron, then quickly apply

full power and full down elevator at the same time, making sure that the aileron controls

are neutralized. The PBF will instantly exit the flat spin and enter a tight outside

loop. After flying through 1/2 of the outside loop, pull back on the elevator stick

to get it flying right side up again.

Please note that these spin recovery techniques are backwards from a normal plane.....but

they work great on the PBF. Once you figure out how to enter and exit these spins on

command, they are a lot of fun!.....especially trying to see how low you can go and still

recover from Inverted Flat Spins! (Video link to PBF Spins, Spin Recovery

Techniques, and oops-I-waited-too-long-to-get-out-of-this-flat-spin at bottom of this

page.)

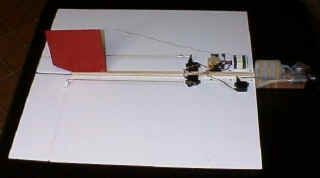

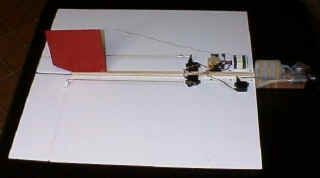

PBF #1

Here's my first version of the PBF that was inspired by

John's Flying Pizza Box. But where John built an airfoiled wing by forming two

sheets of 2mm coroplast around a spar, I decided to go with a single flat piece of

4mm (3/16") coroplast for the wing. This made the PBF lighter, much simpler and

easier to build, and much easier to mount the motor. I've been mail ordering my 4mm

coroplast from Harbor Sales, but

your local sign making business will have it too.

Here's my first version of the PBF that was inspired by

John's Flying Pizza Box. But where John built an airfoiled wing by forming two

sheets of 2mm coroplast around a spar, I decided to go with a single flat piece of

4mm (3/16") coroplast for the wing. This made the PBF lighter, much simpler and

easier to build, and much easier to mount the motor. I've been mail ordering my 4mm

coroplast from Harbor Sales, but

your local sign making business will have it too.

PBF #1 was powered by an HB .15, and weighed 1 lb., 12 oz. with three Futaba S-133

servos, a 110 mah battery, and an antique Royal AM receiver. Even though it didn't

have a rudder, it flew great! It could loop, roll, fly inverted, and fly around in

high alpha flight with the nose pointing up at over 60 degrees. It flew so well,

that I posted detailed photos on RC

Universe.Com of this plane so others could build a PBF of their own. After that,

many more people started building their own versions of the PBF, and each one was a little

different. Over time, the PBF began to evolve to it's current state of the

art......and the PBF is still evolving.

PBF + Hovering = No-Brainer

The PBF was a LOT more fun to fly after I added another S-133 servo, a

rudder, and replaced the HB .15 with an old OS bushing .25 engine! The rudder and

the extra power of the OS .25 made the PBF even more maneuverable, and much more fun to

fly. The improved PBF would now easily loop both inside and outside, spin both

upright and inverted, roll, hover, and even hang on the prop. But consecutive max

performance loops would bog down the OS .25, and it would barely climb out of a vertical

hover. It was fun to fly, but I wanted more power, without adding much more

weight. Experience had also revealed some areas that needed to be stronger, and

other areas that were over-built and could be lightened and/or simplified. So a

second PBF was designed and built.

The PBF was a LOT more fun to fly after I added another S-133 servo, a

rudder, and replaced the HB .15 with an old OS bushing .25 engine! The rudder and

the extra power of the OS .25 made the PBF even more maneuverable, and much more fun to

fly. The improved PBF would now easily loop both inside and outside, spin both

upright and inverted, roll, hover, and even hang on the prop. But consecutive max

performance loops would bog down the OS .25, and it would barely climb out of a vertical

hover. It was fun to fly, but I wanted more power, without adding much more

weight. Experience had also revealed some areas that needed to be stronger, and

other areas that were over-built and could be lightened and/or simplified. So a

second PBF was designed and built.

PBF #2

My second PBF incorporated several major

construction improvements. The spine was moved to the bottom of the wing, and was

built from a piece of 1/2" aluminum U-Channel. This allowed the spine to fully

extend from the leading edge to the hinge line. Moving the spine under the wing made

it simple to fasten the motor mount beams directly to the spine, which further

strengthened the structure. The bottom mounted spine also made it easy to fasten the

fin/rudder with a couple of 1/4" x 20 nylon screws, which in turn secured the rear

section of the 4mm coroplast wing to the spine itself.

My second PBF incorporated several major

construction improvements. The spine was moved to the bottom of the wing, and was

built from a piece of 1/2" aluminum U-Channel. This allowed the spine to fully

extend from the leading edge to the hinge line. Moving the spine under the wing made

it simple to fasten the motor mount beams directly to the spine, which further

strengthened the structure. The bottom mounted spine also made it easy to fasten the

fin/rudder with a couple of 1/4" x 20 nylon screws, which in turn secured the rear

section of the 4mm coroplast wing to the spine itself.

The motor mount beams were originally made from pine, but later replaced with beams made

from oak. The motor mount beams were fastened directly to the aluminum U-channel,

creating a much stronger unified structure. The stronger motor mount and spine

assembly no longer needed a doubler on top of the wing, so the plastic doubler used in the

first PBF was eliminated. To further speed up construction time, no glue was used.

Everything was fastened with either screws, double-stick foam tape, velcro, or

zip-ties. These improvements dramatically simplified and sped up the construction,

while increasing the overall strength of the PBF #2.

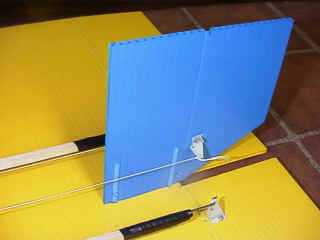

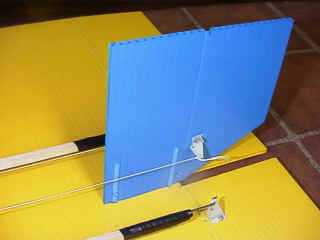

Coroplast Hinges

Making hinges in coroplast is extremely easy!

Just follow these simple step by step instructions

Step 1: Locate the flute nearest the desired hingeline.

Step 2: Cut and remove the material on one side of the flute.

Step 3: Leave the opposite side of the flute intact.

Step 4: Presto! You've just created an instant and durable hinge!

Bolt-On Vertical Fin

The 1/4 x 20 x 2" nylonbolts

pass through the

The 1/4 x 20 x 2" nylonbolts

pass through the

U-channel, then through the 4mm coroplast wing,

and end up threading into the flutes of the vertical fin.

This holds the rear of the wing tightly to the U-channel,

while securing and automatically aligning the

4mm coroplast vertical fin.

It works great!

Mounting the Servos

Figure out the locations of the servos using the

photos of PBF #2 and PBF #3 as a guide.

Figure out the locations of the servos using the

photos of PBF #2 and PBF #3 as a guide.

Clean the coroplast and the servo case with rubbing alcohol and let thoroughly dry.

Use 1/2" wide by 1/16" thick double stick foam mounting tape to fasten the

servos to the coroplast. Use one strip on the bottom of a servo, and two strips on

the side of a servo. (Wal-Mart carries rolls of double stick foam tape in the

masking tape and duct tape section.)

To make sure the servos stay stuck to the foam tape, especially in hot weather, poke some

holes through the coroplast as needed so you can zip tie each servo to the wing.

Don't rely solely on the double stick foam tape, or solely on zip ties or the servos

could shift their positions, resulting in constant trim changes.

Mounting the Receiver & Battery

Mount the receiver with 1/2" wide sticky backed velcro strips. (Available from

Wal-Mart in the sewing section). Be sure to clean the coroplast wing and receiver

case with rubbing alcohol before applying the velcro strips. Use a single strip of

the hook material on the wing, and a single strip of the loop material on the bottom of

the receiver case. The idea here is for the receiver to stay put.....but also be able to

wiggle freely enough to isolate it from the engine vibration. With 270 ma and smaller

batteries, the same velcro mounting method also works great!

Don't think velcro is strong enough to hold a receiver or battery?

Just wait until you try removing them!

Mounting the Fuel Tank

Try to keep the fuel tank as close as possible to the engine to avoid fuel draw problems

during nose high flight.....which is pretty much the whole flight.

Mount the fuel tank with velcro the same way as the receiver and battery. The sewing

section of Wal-Mart also has some sticky backed "Industrial Strength Velcro"

that is about 2.5" wide. This works great for the fuel tank, and also works

great for mounting standard size battery packs.

Or install some hooks on either side of the fuel tank, place some foam rubber under the

tank, and use a single #64 rubber band to hold it all in place.

Mounting the tank with velcro or a rubber band will keep the fuel from foaming.

Don't use zip ties, glue, or too many rubber bands to fasten the fuel tank or the engine

vibration will cause the fuel to foam......which will result in erratic engine runs.

Programming the Radio

The goal here is to set the travel adjustments and the dual rates so that a full up or

full down stick command runs both servos to their maximum travel allowed by the

transmitter, and a full left or full right aileron command will also run both servos to

their maximum travel allowed by the transmitter. When the servo travel settings and

the dual rate settings are correct, combining an elevator and aileron stick command on the

high rate setting will simply cause one servo to travel back towards neutral, while the

other servo won't move at all since it was already at it's maximum travel.

NOTE: Mechanical adjustments are then made to get the proper initial elevon throws

of 2" up, and 2" down.

The following recommended settings should be fairly close,

but may require some tinkering with the high dual rate settings to actually achieve the

goal stated above.

**********************************************************************

Futaba (Hitec)

Activate the ELEVON program.

Set the elevator, aileron, and rudder ATV (EPA) adjustments settings to the maximum, (140%

on the 8U and 9C, and 120% on the 7U and 6X).

Set the elevator, aileron, and rudder HIGH RATE adjustments to 100%, and adjust all LOW

RATE settings to 60%.

Adjust all ELEVON mix settings to either 100% or -100%, depending on the direction of

travel of the servos needed to get the proper direction of elevon throws.

Adjust the EXPO setting on the elevator, aileron, and rudder to -60% on HIGH RATES, and

-40% on LOW RATES.

(Note: Futaba and Hitec use NEGATIVE values for EXPO.)

**********************************************************************

JR

Set the wing type to DELTA.

Set the elevator, aileron, and rudder TRAVEL ADJUSTMENT settings to the maximum, (150%).

Set the elevator, aileron, and rudder HIGH RATE adjustments to 100%, and adjust all LOW

RATE settings to 60%.

Adjust the EXPO setting on the elevator, aileron, and rudder to 60% on HIGH RATES, and 40%

on LOW RATES.

(Note: JR uses POSITIVE values for EXPO.)

**********************************************************************

Airtronics

From the "ETC" menu, select the ADVANCED program mode.

Scroll down and switch the DELTA flight mode to ON.

Set the elevator, aileron, and rudder EPA settings to the maximum, (150% on the RD6000).

Set the elevator, aileron, and rudder HIGH RATES to 130%, and adjust all LOW RATES to 80%.

Adjust the EXPO setting on the elevator, aileron, and rudder to 60% on HIGH RATES, and 40%

on LOW RATES.

(Note: Airtronics uses POSITIVE values for EXPO.)

(Airtronics setup info courtesy of my buddy Pepe, the first PBF pilot in Mexico.)

Control Linkages

The 1/4 x 20 x 2" nylon bolts thread into the

flutes of the vertical fin to secure it. These nylon bolts also serve to hold the

rear wing section tightly to the spine.

The 1/4 x 20 x 2" nylon bolts thread into the

flutes of the vertical fin to secure it. These nylon bolts also serve to hold the

rear wing section tightly to the spine.

The pull-pull threads are tied to the rudder control horns. I've tried Kevlar, upholstery

thread from Wal-Mart, and 6 lb. test monofilament fishing line. The upholstery

thread has proven to work the best, and it's dirt-cheap at 150 yards for less than two

dollars.

Z-bends were used at the elevon control horns instead of clevises. If necessary,

adjustments can be made at the EZ connector on the servo arm. Linkages are simple,

lightweight, and cheap!

Light and Rigid Pushrods

The elevon pushrods are made from 1/4" square

hard balsa to eliminate flexing when they are pushing on the elevons. An L-bend in the

wire is inserted into a hole in the balsa about 1.5" from the end. Apply a

little medium CA where the wire lays on the balsa, and then wrap the end with electrical

tape. The longer you make the balsa pushrod, the less chance the pushrod will bend and

flex when pushing on the elevons. And since the balsa is light, it just might save

your servo's gear train in a crash.

The elevon pushrods are made from 1/4" square

hard balsa to eliminate flexing when they are pushing on the elevons. An L-bend in the

wire is inserted into a hole in the balsa about 1.5" from the end. Apply a

little medium CA where the wire lays on the balsa, and then wrap the end with electrical

tape. The longer you make the balsa pushrod, the less chance the pushrod will bend and

flex when pushing on the elevons. And since the balsa is light, it just might save

your servo's gear train in a crash.

Super Simple Pull-Pull Setup

The pull-pull linkage is first started by tying a thread to each of the rudder control

horns. Cut the thread to length at least 6 inches past the servo arm. Now lace

the thread through all of the holes in the servo arm, starting with the outer hole, and

ending up with the inner hole. You should end up with several inches of thread

leftover after finally passing through the inner hole.

The pull-pull linkage is first started by tying a thread to each of the rudder control

horns. Cut the thread to length at least 6 inches past the servo arm. Now lace

the thread through all of the holes in the servo arm, starting with the outer hole, and

ending up with the inner hole. You should end up with several inches of thread

leftover after finally passing through the inner hole.

With the servo in the neutral position, and the servo arm straight across, and the rudder

in the neutral position, pull the slack out of one of the threads. Then pull the

slack out of the other thread until the rudder stays in the neutral position.

Finally the ends of each of the threads are secured by passing each of the threads

underneath the head of the servo arm hold down screw, and then tightening the screw.

Again, I've tried Kevlar, 20 lb. test Spiderwire, 6 lb. test monofilament fishing line,

and upholstery thread from Wal-Mart. The upholstery thread has proven to work the

best by far, and it's dirt-cheap at 150 yards for less than two dollars.

NOTE: Do not wrap the threads much more than 1/2 turn around the screw or the pull-pull

thread may get cut by the screw threads as the screw is tightened. The idea here is

to simply pinch the thread between the screw head and the servo arm.

PBF + OS 40FP = FUN

To power PBF #2, I chose an OS 40FP. The OS 40FP weighs

the same as the expen$ive ball bearing .25 to .32 size engines, and has similar usable

power. For many years, the OS 40FP has been one of my favorite engines for sport

flying the Stickit

type planes due to it's excellent running and throttling characteristics. Since the

PBF is basically a hovering and 3D plane, I figured an OS 40FP would work just as well on

a PBF. Also I wanted to see if the weight of using a standard size airborne radio

would adversely affect the flight performance......(It didn't!)

To power PBF #2, I chose an OS 40FP. The OS 40FP weighs

the same as the expen$ive ball bearing .25 to .32 size engines, and has similar usable

power. For many years, the OS 40FP has been one of my favorite engines for sport

flying the Stickit

type planes due to it's excellent running and throttling characteristics. Since the

PBF is basically a hovering and 3D plane, I figured an OS 40FP would work just as well on

a PBF. Also I wanted to see if the weight of using a standard size airborne radio

would adversely affect the flight performance......(It didn't!)

Servos are Futaba S-148, receiver is a R-128DF, but the battery is a 270 mah from Radio

Shack. The empty weight came out to be 2 lbs., 8 oz. Surprisingly, even though

the PBF #2 came out heavier than the first PBF #1, this second generation PBF #2 flew even

better! The extra power of the OS 40FP made a big improvement in the overall

maneurverability, giving PBF #2 plenty of reserve power to climb vertically out of hovers

and torque rolls, especially with a 10x4 prop.

Improved Spine and Motor Mount

On the third generation PBF, the aluminum spine was replaced with a much

lighter 3/8" x 3/4" pine spine. The motor mount beams are also made of

3/8" x 3/4" pine, but I'd recommend using oak or maple motor mounts. I

took a slight step backwards here and glued the motor mount beams to the spine, but these

are the only parts that are glued together. Everything else assembles with screws

just like the second generation PBF #2. The pine spine has proven to be plenty

strong enough, is at least a couple of ounces lighter, and always springs back to straight

after a crash unlike the aluminum U-channel.

On the third generation PBF, the aluminum spine was replaced with a much

lighter 3/8" x 3/4" pine spine. The motor mount beams are also made of

3/8" x 3/4" pine, but I'd recommend using oak or maple motor mounts. I

took a slight step backwards here and glued the motor mount beams to the spine, but these

are the only parts that are glued together. Everything else assembles with screws

just like the second generation PBF #2. The pine spine has proven to be plenty

strong enough, is at least a couple of ounces lighter, and always springs back to straight

after a crash unlike the aluminum U-channel.

In fact, the pine spine and motor mount assembly has worked so well, that I upgraded the

first version PBF #1 from a top mounted balsa spine to the bottom mounted pine

spine. And while I was at it, I replaced the OS .25 with a Webra .32 for awhile, but

later replaced the Webra 32 with a Norvel Big Mig 25 which made PBF #1 even more fun to

fly!

After breaking three motor mounts on PBF #2, the aluminum spine was also replaced with the

newer pine spine design. I'm guessing that the aluminum was too stiff and was

resulting in the motor mounts having to absorb all of the impact stress from a crash.

The pine spine is stiff enough to do the job, but apparently is flexible enough to

absorb some of the stress during a crash, thus saving the motor mounts from breaking.

Upgrading PBF #2 to a pine spine and motor mount resulting in a weight loss of a

couple of ounces. I also replaced the OS 40FP with a mousse can piped Thunder Tiger

Pro .36 engine. Although it doesn't throttle quite as well as the 40FP, the piped TT

36 gave PBF #2 a LOT more power! I really like the extra power, but I'm not sure the

loss of precision throttling is worth it. I need more flying time with PBF #2 to

decide for sure.

PBF #3

PBF

#3 is powered by a TT 42GP with a Mousse Can Pipe (MCP), spinning a 10x4 MA prop.

The radio was arranged to clear the MCP by laying the throttle servo behind the tank, then

attaching the rudder servo on top of the throttle servo. The elevon servos were

mounted upright to keep them as close to the center as possible to avoid interfering with

the MCP.

PBF

#3 is powered by a TT 42GP with a Mousse Can Pipe (MCP), spinning a 10x4 MA prop.

The radio was arranged to clear the MCP by laying the throttle servo behind the tank, then

attaching the rudder servo on top of the throttle servo. The elevon servos were

mounted upright to keep them as close to the center as possible to avoid interfering with

the MCP.

Airborne uses a Futaba 127DF rx, 270mah 4.8 volt battery, Futaba S-128 on throttle, Futaba

S-132H high speed BB servos on elevons and rudder. Dry weight is 2 lbs, 6 ounces. A

strip of Velcro runs between the elevon servos and the fin so I can rearrange the receiver

and battery to change the CG. PBF #3 is now flying with the CG at 6.0" back

from the leading edge.

The rubber bands holding the fuel tank were replaced with some "Industrial Strength

Velcro" that I bought at Wal-Mart. It worked so well, that I converted PBF G2

to a velcro fuel tank mount.

The TT 42GP with the MCP runs and throttles just as well as the OS 40FP, but has

considerably more power. Vertical acceleration from a hover or torque roll is

unreal, and it easily powers it's way through continuous high drag maneuvering. PBF

#3 with the TT 42GP and MCP is fast becoming my favorite of the three PBFs I currently

have flying.

I made about 20 kits of the PBF #3 for my local flying buddies. Within just a few

weeks they were all sold out. In the Lake of the Ozarks area, the PBFs are

spreading!

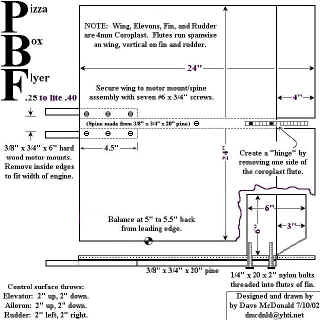

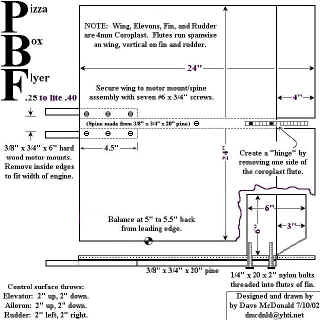

PBF Plans

Would you like to build a PBF? Click on the plans to enlarge

them. When combined with this web page, these plans should give you enough

information to build and fly your own PBF.

Need an Elevon Mixer?

To get the maximum enjoyment out of flying a PBF, a computer transmitter

with elevon mixing works best. But for those of you who don't have a computer

transmitter and still want to fly a PBF, I've got great news!

I recently stumbled upon a neat little electronic elevon mixer from Bill-Tek Electronics that works

perfectly in a PBF! It's a small lightweight electronic device that plugs inbetween

the receiver and servos that mixes the aileron and elevator commands to give elevon

control. In fact, I bought a couple of these electronic elevon mixers just to see

for myself how well they would work in a PBF, and they worked great!

The Bill-Tek Electronics elevon

mixer is lightweight, simple to use, and is very inexpen$ive. For example, the kit

version of the Bill-Tek Electronics

elevon mixer only cost $11.00, plus a few bucks shipping. Even the factory assembled

electronic elevon mixer from Bill-Tek

Electronics only costs $17.00, plus a few bucks shipping.

If you're looking for an inexpensive electronic elevon mixer to get a PBF flying with a

non-computer transmitter, the one from Bill-Tek

Electronics would be hard to beat.

Questions? Click on this link to send

Bill an email to ask about getting an Elevon Mixer for your PBF. And

please let Bill know that you found out about his elevon mixer on this PBF web page.

PBF Action Videos Now Online!

My buddy Shaun "Mud Duck" Zimmerman has posted several photos and videos of

these three PBFs in action on the Jefferson

City Radio Control web site under the Club News section.

Shaun's videos show my PBFs doing loops, spins, rolls, slow flight, hovers, torque rolls,

touch and goes, catch and goes, prop-wash combat, and even crashing. Also shown are

a few different methods of hand launching a PBF, including a barrel roll hand

launch. And there is also a video of Shaun flying his own PBF for the very first

time.

Here's the link to Shaun's

PBF Photos and Videos, Page 1 if you want to see all three of my PBFs in action,

including loops, rolls, spins, hovers, touch and goes, catch and goes, and torque rolls.

Here's the link to Shaun's

PBF Photos and Videos, Page 2 that shows the Norvel 25 powered PBF#1 doing some low

level wild and crazy flying....including taking off and landing from a folding chair.

Here's the link to Shaun's PBF Photos

and Videos, Page 3 that shows the Norvel 25 powered PBF#1 doing some windsock touch

and goes,

plus a 36"x36" Super PBF that was built and flown by my nephew, Bryan.

Here's the link to Shaun's

PBF Photos and Videos, Page 4 that shows the TT 42GP powered PBF#3 doing some wild and

crazy flying, plus a brief glimpse of PBF combat with streamers.

NOTE: You may need to update

your Windows Media Player in order to view the videos.

If that doesn't work, try using Quicktime 4.0 to play the videos.

PBF Alter Ego

If you liked my PBF web page,

you will also want to check out a similar square flying wing by James Goss that he calls a

flying Postage Stamp.

If you liked my PBF web page,

you will also want to check out a similar square flying wing by James Goss that he calls a

flying Postage Stamp.

James has been experimenting with his own version of a square flying wing by adding

landing gear, wingtip plates, dual rudders, dual elevons, pusher engines, flaps, and other

crazy stuff just to see what works.....and what doesn't. The popup ads on James' web

site are annoying, but worth the effort to find out what this creative genious is going to

try next!

Check out James Goss Model Aviation

for more information.

NOTE: If this page looks strange at times,

it's probably just me making changes again.

Comments?

E-Mail me at:

dmcdnld@yhti.net

(To Dave McD's PREDATOR)

(Back to R/C

Air Force)

(Home)

The PBF has also proven to be nearly indestructible. In fact, the more I fly it, the

more the PBF reminds me of a Realflight plane instead of a real plane. Unlike any of my

other RC planes, I've pretty much lost my fear of damaging the PBF in a crash......which

is one of the things that makes it so much fun to fly! If you dork the PBF, you

usually just restart the engine and go flying again....sort of like the spacebar on

Realflight.

The PBF has also proven to be nearly indestructible. In fact, the more I fly it, the

more the PBF reminds me of a Realflight plane instead of a real plane. Unlike any of my

other RC planes, I've pretty much lost my fear of damaging the PBF in a crash......which

is one of the things that makes it so much fun to fly! If you dork the PBF, you

usually just restart the engine and go flying again....sort of like the spacebar on

Realflight. Original design inspired from an idea

Original design inspired from an idea

If you liked my PBF web page,

you will also want to check out a similar square flying wing by James Goss that he calls a

flying Postage Stamp.

If you liked my PBF web page,

you will also want to check out a similar square flying wing by James Goss that he calls a

flying Postage Stamp.