How to Modify a Futaba S-148

for 180 Degree Operation

Text and Photos by:

Dave McDonald

AMA 40128

(dmcdnld@yhti.net)

Did you ever need a servo that rotated 180 degrees to

run a cheap pair of mechanical retracts? And did you cringe at the thought of

spending twice as much money just for that retract servo.....than you paid for your

retracts themselves?

Or........

Did you ever wish you had a fully proportional servo

that rotated 180 degrees to operate your flaps?......but you couldn't find one

anywhere......at any price?

UPDATE:

I think I owe Airtronics an apology here! It has been brought to my attention that

the Airtronics 94739 is a 170 degree proportional double ball bearing servo that is

similar in size to the Futaba S-148, but with nearly twice the torque.

The Airtronics 94739 servo lists for about 100 dollars with a street price of about 70

dollars.

Thank you Jack Albrecht for bringing this to my attention!

This procedure will explain how to easily modify a

standard Futaba S-148 into a servo that travels 180 degrees instead of the usual 60

degrees. But unlike a dedicated retract servo, this modified S-148 will still be

fully proportional.

Modifying the electronic circuit only requires adding 2

new resistors to the

S-148 circuitry. It isn't diffiult to do.....BUT......because of the

very limited space inside the S-148 servo, and the small size of the S-148 circuit board,

I don't recommend that you try this unless you are experienced at soldering and

desoldering small electronic circuits.

And now that the disclaimer is out of the way,

here's how I did it: :-)

Materials needed:

You'll only need a total of 2 new resistors for this

project.

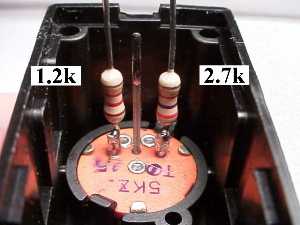

One is a 1.2k resistor, 1/4 watt. (brown, red, red)

The other is a 2.7k resistor, 1/4 watt. (red, violet, red)

Disassembling the Futaba S-148 Servo:

- Remove the servo arm and hold down screw.

- Remove the (4) bottom case screws, and the bottom case cover.

- Remove the top section of servo case.

- Remove all of the servo gears from the middle section of the servo case.

- Remove both of the small screws holding the motor to the servo case

middle section.

- De-solder the three feedback pots leads from the circuit board.

(See photo on left) Be sure all three leads are COMPLETELY de-soldered before going

to the next step! (Note: Solder wick works best!)

- Carefully push both the motor and the circuit board out of the middle

servo case section, leaving the feedback pot in it's original position.

- Before removing the feedback pot from the middle case, place a mark of

some sort on the pot and the case that will help to identify the correct orientation later

during the reassembly process.

- Carefully remove the feedback pot from the middle servo case section.

Modifying the Futaba S-148 Servo

for 180 Degree Rotation:

- Locate the two outer leads of the feedback potentiometer, and leaving

about 1/4 inch of the leads sticking out of the bottom of the feedback pot, cut off the

excess leads. (Note: Do NOT cut the center lead!)

- Double check the circuit board to make sure that the three holes in the

circuit board are left fully open. De-solder again if necessary. (Note:

Solder wick works best!)

- Prepare both new resistors by trimming ONE of the leads off of each

resistor down to about 1/4 inch in length. Leave the other lead of each resistor

full length.

- Pre-tin the shortened resistor leads on both resistors.

- Pre-tin both of the shortened outer feedback pot leads.

- Refer to the photo on the left for the next four steps.

- Orient the feedback pot into a similar position as the photo, so you are

looking directly at the lead side of it, and the leads sticking out of the pot appear to

be in the eleven, twelve, and one o'clock positions.

- Referring to the photo, solder the 1/4 inch lead of the 1.2k resistor to

the 1/4 inch lead of the feedback pot that is in the Eleven O'Clock position. (Note:

The end of the short resistor lead should be up against the base of the pot before

soldering.)

- Again referring to the photo, solder the 1/4 inch lead of the 2.7k

resistor to the 1/4 inch lead of the feedback pot that is in the One O'Clock position. (Note:

The end of the short resistor lead should be up against the base of the pot before

soldering.)

- Re-install the feedback pot into the middle servo case section, using

the photo shown above, and your mark that you made earlier, to insure correct alignment.

- Carefully place the motor/circuit board assembly back into the middle

section of the servo case by threading the two resistor leads through the two outer holes,

and the center pot lead back into the center hole. Push on the motor and circuit

board until they are fully seated back into the proper position.

- Re-install the two motor hold down screws.

- Solder the 1.2k resistor lead, the 2.7k resistor lead, and the center

lead of the feedback pot to the circuit board, and trim off the excess leads. (Note:

Do NOT use too much solder here, or the excess solder could run down inside of the servo,

possibly causing a short circuit!)

- Re-install the entire servo geartrain back into the middle section of

the servo case. Be sure the output gear is installed correctly before proceeding to

the next step. (Note: With the feedback pot shaft in the middle position of

it's rotation, install the output gear in the position shown. If it's on backwards,

the molded "tab" on the output gear won't let the top/middle gear fit

correctly.)

- Place the case top section back into the proper position.

- Place the case bottom section back into the proper position.

- Re-install the 4 screws that hold the servo together.

Do NOT allow the modified servo to try

to rotate beyond the mechanical limits of the geartrain!!!

If necessary, adjust your transmitter's

ATV to avoid over driving the servo!!!

Please let me know how your 180 degree modification

project worked out!

Just click on one of these links and

Send your comments to:

Thanks

Dave!

My

180 Degree Futaba S-148 Works Perfectly!

or

Dave,

I've Got a Problem with My 180 Degree S-148!

or

Dave,

you S.O.B.!!!!

You

Made Me Ruin a Perfectly Good S-148!

NOTICE:

Although I'm granting free access to view this web page at

no charge, the text and photos within this article may NOT be reproduced, nor may they be

used for profit without the expressed written permission of the author, Dave McDonald.

Comments?

E-Mail me at:

dmcdnld@yhti.net

(Back To Dave

McD's ULTRA SPORT 40 ARF)

(Back to R/C

Air Force)

(Home)